What is Design for Manufacturing?

- mtanaka

- Apr 3, 2019

- 3 min read

Design for manufacturing (DFM) is an important element of the product development process. DFM takes into account the manufacturing process that will be used to fabricate each component to improve product quality and reduce cost. This is done very early in the design process, enabling engineers to optimize the product design to take advantage of process capabilities and avoid processing limitations. While DFM is useful throughout the product development process, it has the greatest potential when used during the early stages of product development before the design details are finalized.

The first step in using design for manufacturing is to develop an understanding of the common manufacturing processes used to fabricate products. Examples of these include milling, turning, casting, injection molding, and laser cutting. Begin by learning how the manufacturing process would be used, its process capabilities, strengths, weaknesses, and limitations. By developing an understanding of several different manufacturing processes, you will be able to select the one best suited for your component design, including considerations of production volume and dimensional tolerances as well as robustness. Most products consist of multiple components and the best process for one component will not necessarily be the best process for another.

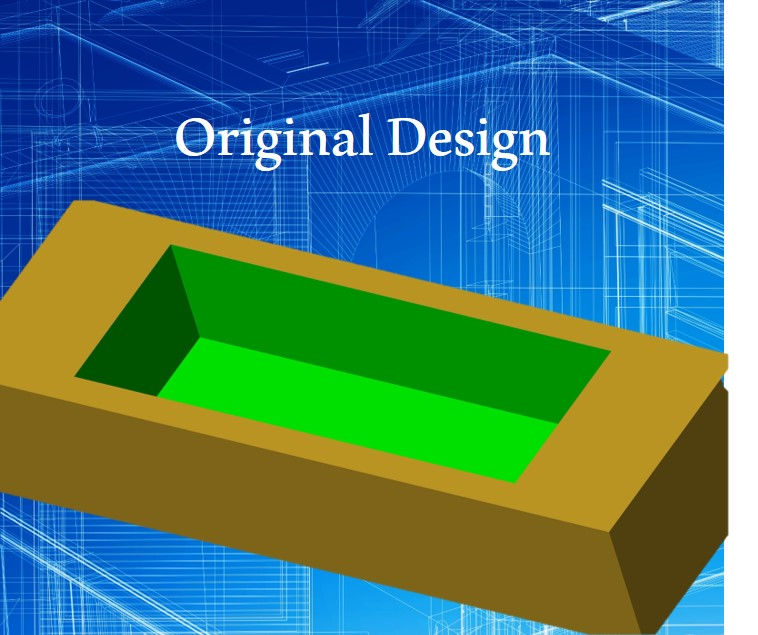

After developing an understanding of the processes used to manufacture components and selecting one for your product, the next step is to optimize the design for that specific process. Many DFM principles can be applied quite easily. Here is an example to illustrate this point. Consider using DFM to improve the design of a pocket cut into a steel part using a CNC milling machine. The function of the pocket is to hold a sensor and provide adequate clearance. The initial design of the pocket was created using the 3D CAD model software as a rectangular opening with sharp corners.

DFM is applied by first understanding the manufacturing process. CNC mills use round cutting tools (end mills) to remove material from the workpiece. Larger diameter tools remove more material with each pass than smaller tools. To cut a slot with sharp corners, a large diameter is initially used to quickly remove the bulk of the material, but this will leave rounded edges in the inside corners of the pocket. Next the tool is changed to a smaller diameter tool and additional material is removed from each of the each of the four corners. Using this process, a pocket can be produced in a part with a corner radius equal to half the diameter of the smallest tool. However, if a truly sharp corner is needed, it cannot be manufactured using the normal milling process – a limitation of the technology. An additional process such as electrical discharge machining (EDM) would be required.

In this example applying DFM to the design is easy. Add rounds to the corners of the 3D CAD model with sufficient radius to enable the pocket to be produced with a single tool of sufficient diameter to achieve the milling operation in a reasonable time. However, because the corner is no longer sharp it may require the pocket size to be increased slightly to still accommodate the sensor. This may drive other dimensions to change as well. If the pocket is made larger, the outside dimensions of the part may also need to increase to maintain sufficient thickness of material between the pocket and the outside of the part. This is usually easy at the design stage when the entire assembly of parts are 3D CAD models. It becomes more difficult and often prohibitively expensive to make manufacturing changes after tooling for the mating parts have been completed.

In addition to the simple example above, there are a multitude of other DFM techniques that can be applied to improve product designs. Some of these are associated with the design of components while others are associated with improving the assembly of products (a.k.a. Design for Assembly). Because DFM makes products easier to manufacture, it also improves product quality while simultaneously decreasing product cost.

About the Author: Martin Tanaka is an Associate Professor at Western Carolina University who specializes in product design and development. He has eleven years of experience designing commercial products in industry and nine years of experience assisting local companies with product innovation. Dr. Tanaka has a Ph.D. in engineering and is a licensed professional engineer in the state of North Carolina

Copyright 2019 Martin Tanaka

Comments